The evolution of our tortilla making process

Back in 2015 we started pressing our fresh soft corn tortillas for our award-winning taco truck with the traditional cast iron tortilla press. A device with two round surfaces which crush masa dough balls into round tortillas. Plastic sheets or greaseproof paper are generally used and for anyone who has used one of these you’ll understand the challenges of getting the tortillas thin enough. It didn’t last long…

Tortillas per hour: 20-30

Tortillas per hour: 20-30

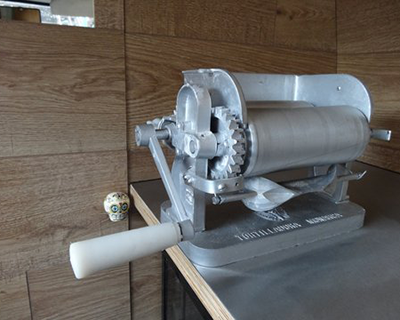

We quickly moved onto the manual tortilladora which looks a bit like a pasta machine. These things take hours and hours of practise and getting the consistency of the masa correct and the machine clean is the key. By the end of 2015 we had shifted to this manual tortilladora which allowed us to adjust the thickness and make perfectly round tortillas fresh before a trade.

Tortillas per hour: 100-200

Tortillas per hour: 100-200

And here she is. “Maria” our brand spanking new tortilla machine. Made in San Luis Potosi, Mexico and transported on a shipping container into Bristol, UK.

The machine stands over 2 metres long and runs on a combination of electricity and LPG. The masa (corn flour) is mixed and then fed in between two rollers and cut before heading down a conveyor belt into the oven. The tortillas are then lightly toasted perfectly (you can tell because they puff up beautifully) and are stacked into a hopper at the end.

Our freshly made tortillas are now available to buy in bulk wholesale and collect fresh and still warm from the machine.

Tortillas per hour: 500-720

LOOKING TO BUY TORTILLAS?

Head over to our store to start ordering the best tortillas in the UK